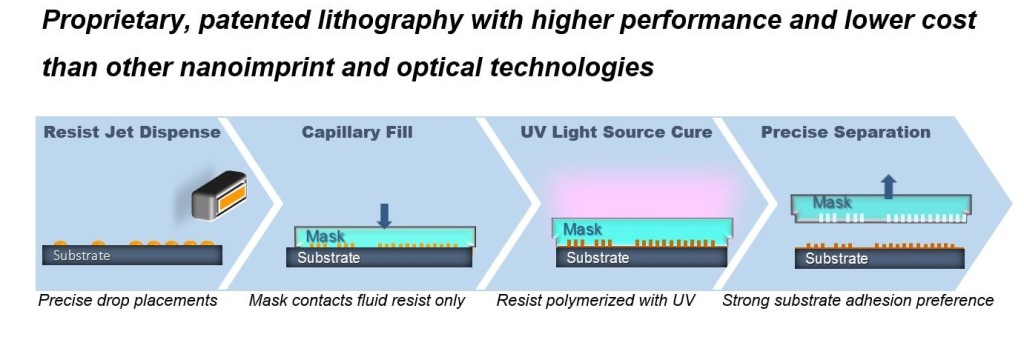

Jet and Flash Imprint Lithography (J-FIL) process uses low viscosity UV imprint fluid where an array of small drops of the imprint fluids is dispensed (See Figure below) in a drop-on-demand manner depending on the pattern density variations of the imprint mask. This ability is critical to a variety of applications including silicon ICs and patterned media, and any application involving non-regular patterns. This adaptive material deposition combined with low viscosities provides the ability to handle arbitrary pattern densities, specifically leading to a process which provides tight control of residual layer which results in more consistent etch and critical dimension uniformity.

The ability to manage arbitrary feature geometries and variable pattern densities while maintaining throughput is a unique characteristic of J-FIL. For example, the use of spin-on materials leads to non-uniform template pressure distribution which is further aggravated by the presence of pattern density variations. This can result in incomplete or excessive resist filling of the template features resulting in non-uniform residual layer thickness and/or feature voids.

The ability to manage arbitrary feature geometries and variable pattern densities while maintaining throughput is a unique characteristic of J-FIL. For example, the use of spin-on materials leads to non-uniform template pressure distribution which is further aggravated by the presence of pattern density variations. This can result in incomplete or excessive resist filling of the template features resulting in non-uniform residual layer thickness and/or feature voids.

Additional performance benefits of J-FIL are in applications requiring nano-scale layer-to-layer alignment. The uniform low pressure, room temperature nature of J-FIL, and the transparent imprint templates make it particularly attractive for a high-resolution layer-to-layer alignment. Another aspect of J-FIL that assists in the alignment is the presence of a thin layer of low viscosity liquid between the template and substrate.

J-FIL provides additional benefits as follows:

- All J-FIL systems include a self-contained material dispense module which eliminates the separate material-dispensing spin coating system (typically referred to as a “track”) required by spin-on UV or thermal imprint processes, saving millions in capital and valuable clean room floor space.

- Our Drop Pattern Generator technology, incorporated in all J-FIL systems, consume 0.1-1.0% of the resist of traditional spin-on systems, which typically spin-off >99% of the resist. This eliminates a significant waste stream which both saves a significant amount of money, and is environmentally responsible.